How Oqton is disrupting manufacturing software with AI and the way they work

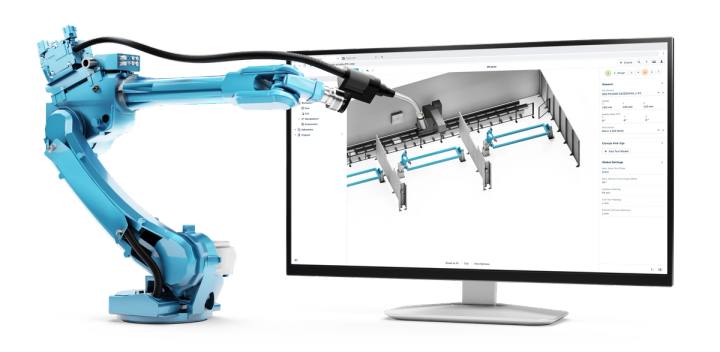

Oqton helps organizations take their manufacturing operations to new levels of efficiency and innovation with AI-powered software for additive production, 3D scanning, and robotic welding. Using Figma and FigJam for visual collaboration across every department, they've increased their productivity dramatically, helping them focus on building great products, rather than suffering through manual processes.

Snapshot

- Industry: Manufacturing Software

- Oqton Employees: 302

- 3D System Employees: 2659

- Figma Plan: Enterprise

- Teams using Figma/FigJam: Product Managers, Designers, Engineers, Brand, Marketing and Events

- No of users: Figma 130, FigJam 600+

- Time savings: 10-35%

- Products: Figma, FigJam

- Integrations: Jira, Slack

Breathing fresh air into manufacturing

Traditionally, companies in manufacturing have struggled with disparate processes driven by complex workflows and clunky user experiences. “In the past, manufacturers used software built by engineers for engineers”, Valentijn Kint, Head of Design at Oqton explains. In recent years, the manufacturing industry has also battled with an aging labor market, with a huge number of skills being lost as experienced designers, engineers, programmers, and operators retired. The challenge for manufacturers has been how to replace those lost skills given the scarcity of new talent entering the industry.

This is the world that Oqton set out to change when they were founded in 2017. The manufacturing industry has witnessed tremendous change over the past few years. Accelerated by the Covid pandemic, manufacturers started the transition to designing and programming in the cloud, driven in part by the availability of manufacturing software on subscription.

Oqton’s strategy was to be at the forefront of new manufacturing technology through the use of cutting-edge AI that captures and automates complex tasks and processes for additive production, 3D scanning and robot welding. By removing manual, complex work through automation, they’re also able to simplify the UX of manufacturing software. The result is an operating system for manufacturing businesses that is machine agnostic and can be used by a much wider group of employees–instead of a select few highly trained technicians.

Reinventing Oqton’s product development process on Figma

Valentijn saw tools like Sketch and Abstract as game changers for design - but he started running into problems at scale. Design files ended up in different silos, and the way they were organized was too complex for his teams to quickly understand what they were looking at and contribute. It was also hard to collaborate and bring other teams into their product development process.

While Figma was on his radar, he wasn't convinced that having an infinite canvas in the browser could work. "I was part of a group of people called Day One Designer. And we were just sharing our experiences and trying to learn from each other. And during one of those meetups, there was a person that was so adamant about Figma. I was like, fine, show me, show me the biggest file you have. Show me what this is. I don't believe it. And so he showed me a really big file and it was super smooth."

Valentijn was surprised by what he saw and began testing Figma with his team. Through testing, the broader Oqton team immediately saw the value of opening up their design process, being able to contribute quickly, and collaborate in real-time from any browser.

With Figma, they were no longer jumping from LucidChart, to Sketch, to Abstract to a prototyping tool anymore. They were no longer swivel chairing through different tabs or uploading and downloading files to share with other teams. There were no more questions on whether they were working on the most up-to-date version or file, and every team could now collaborate and contribute in the same space, on the same project.

"The speed at which our teams can understand and contribute to what they're seeing is unparalleled," Valentijn said.

In fact, Valentijn estimates efficiency savings at 10-35% per employee. “If I can increase productivity by 10% across 50 people, it's like I have 5 extra employees. That makes the value of Figma obvious."

Valentijn explains this efficiency gain using two key metrics:

- Time to Access (the time it takes to access and understand a project)

- Time to Change (the time it takes to understand and contribute value to a project).

The speed at which employees can access, understand and contribute on a visual canvas is what makes Figma so significant for their teams productivity.

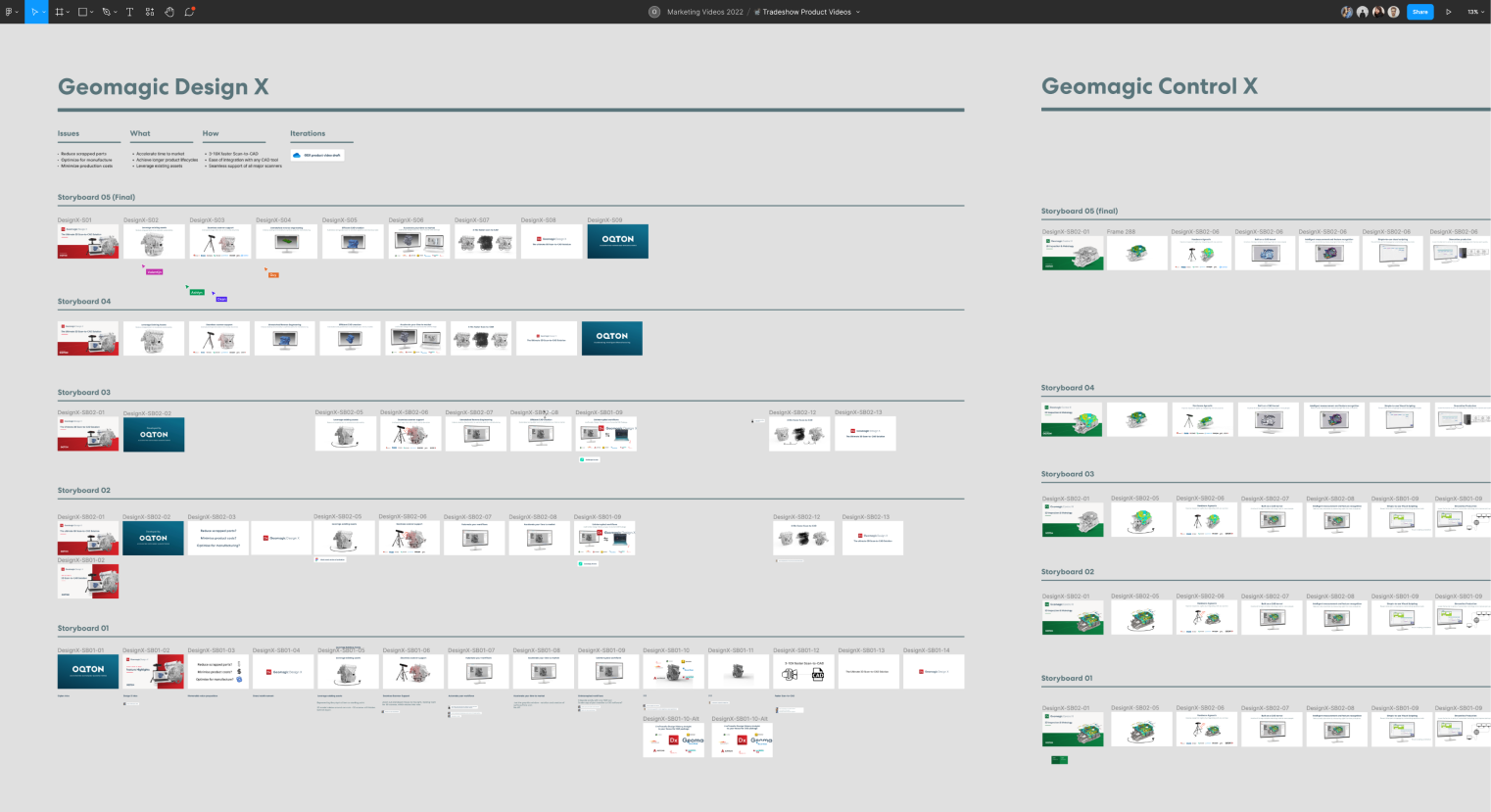

In fact, the benefits of having his team all in one solution were so significant that Valentijn recommended that they use Figma and FigJam for all visual collaboration; across Marketing, Product, and even planning physical events.

Scaling from a startup to acquisition in five years

This realtime collaboration changed the way Oqton worked completely. Changing from working alone, to working collaboratively made the design process as well as handoff and overall team collaboration stronger than ever. In fact, once Oqton started using Figma, they were able to design and work faster from day one. Building products was efficient and aligned across teams – meaning they could focus on the harder, more complex product work, like building out an information architecture and corresponding UI that could scale as an operating system for the manufacturing industry.

Product Managers, Designers and Engineers all collaborate in Figma and FigJam from ideation through to shipping products. And over time, copywriters, marketers, and even event managers began planning and running projects in Figma and FigJam too.

Valentijn's biggest challenge as they grew was keeping up the level of efficiency and speed that they saw when they were a small team. Beyond having teams in one place, building and managing a design system that ensured consistency as they scaled was also a contributing factor. With reusable designs and components, Oqton had no problem maintaining speed as their team grew.

This way of working helped Oqton go from startup to being acquired by 3D Systems for $180 million in 4 years. Valentijn see’s Figma having played a role in that outcome. "Of course all of the people here are the key ingredients to our success, but without Figma, it would have been extremely difficult, Figma has been a huge part of our success."

New demands as part of a larger company

3D Systems didn’t just see value in Oqton’s revolutionary product, they also took notice of the way that teams at Oqton worked. This led to a second transition for the team, with 3D Systems making the move to Figma and FigJam too. Now, with 3D Systems and Oqton working within Figma Enterprise, teams each have their own collaborative workspace and design resources, but admins can also apply permissions and restrictions on which files they can access. This means that teams can work effectively privately, or seamlessly together.

Changing a complex, process-heavy industry by simplifying their employees' experiences

Ultimately, Oqton's focus on using Figma to simplify internal processes, improve their employees time to understanding and contribution in projects, and remove manual tasks has helped them simplify and innovate with their own solutions. In their Manufacturing OS, they've abstracted the complexity by using AI and ML to remove what used to be manual, complex workflows, allowing them to simplify their products, and disrupt a space that relied on technically trained specialist users and admins.

The Total Economic Impact of Figma

This Forrester report shows how teams are using Figma and FigJam to speed up their workflows, consolidate their design stack, and build better products.

See how Figma can help you scale design

Great design has the potential to differentiate your product and brand. But nothing great is made alone. Figma brings product teams together in a fast and more inclusive design workflow.

Get in touch to learn more about how Figma can help companies scale design.

We’ll cover how Figma can help:

- Bring every step of the design process—from ideation, to creation, to building designs—into one place

- Accelerate design workflows with shared company-wide design systems

- Foster inclusivity in the product team process with products that are web-based, accessible, and easy to use